Our Capabilities

We are a multi-platform manufacturer and

full-service partner to category-leading brands.

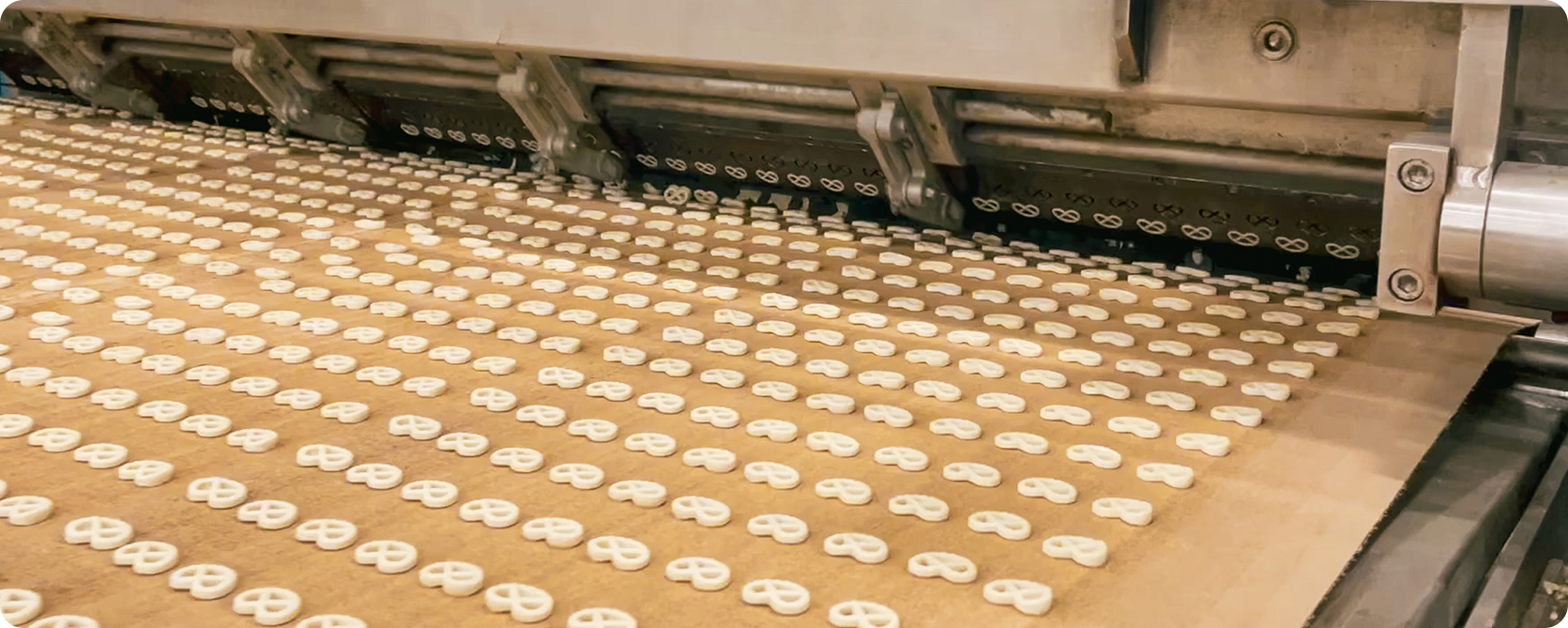

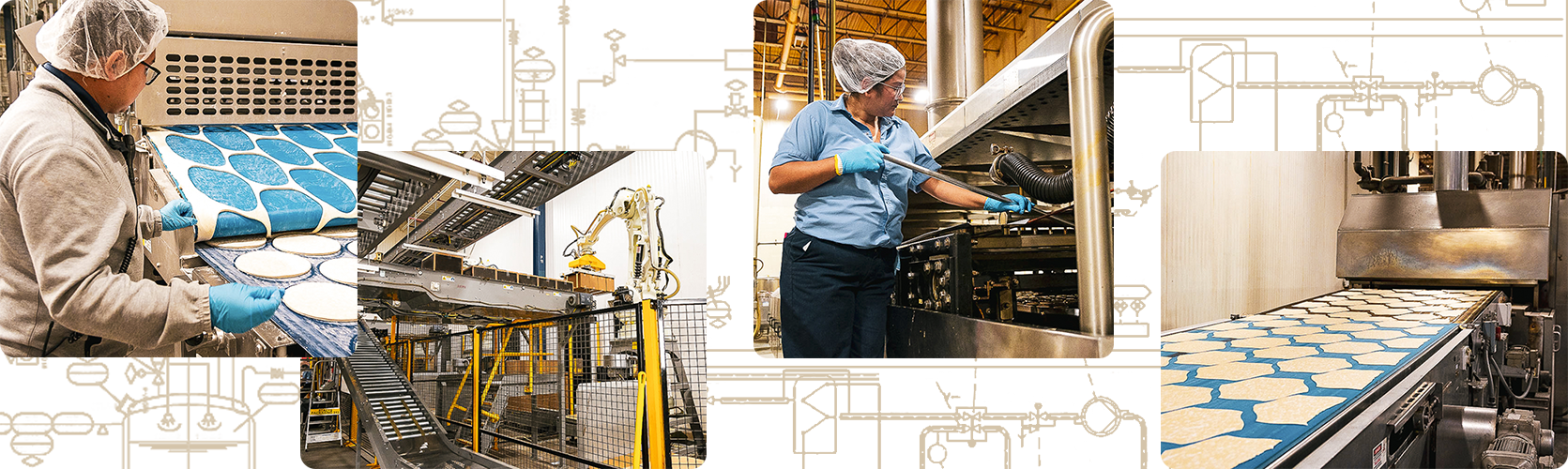

Manufacturing

With a history of building capabilities around attractive category segments, Roskam Foods has grown into one of the largest and most diverse co-manufacturers in the industry. We build long-term partnerships offering transparency, flexibility and exceptional food safety and quality. Our facilities are SQF Level 2 or 3 certified, FSMA compliant and follow Good Manufacturing Practices.

Our production capabilities span numerous platforms and technologies, and we continue expanding what’s possible for our customers every day. Whether building lines from the ground up or modifying systems we already have in place, our experienced team of engineers, product developers, and project managers can bring your ideas to life. Please contact us to start the conversation.

- Dough Mixing (Batch, Continuous)

- Depositing (Dough, Batter)

- Extrusion

- Cold, Low-Pressure Twin-Screw

- Cold, High-Pressure Single Screw

- Sheeting

- Proofing

- Baking

- Tempering

- Drying

- Seasoning (Topical Oil, Slurry)

- Air Popping

- Topical Particulate Application

- Coating

- Caramel Candy

- Chocolate Enrobing & Drizzling

- Slicing, Dicing, Cubing, Shredding

- Multi-Component Snack Blending

- Batching, Blending (Horizontal Ribbon + multi-Component)

- Filling (Super Sack, 50lbs, Retail)

- Batching

- Mixing

- Blending

- Depositing

- Gauging/Sheeting

- Cutting

- Cooking

- Cooling

- Freezing

- Stacking

- Picking

- Organizing/Indexing

- Product Assembly

- Cartoning

-

Twin-Screw Extrusion

-

Direct Expanded RTEC

-

Rings, Puffs, Crisps

-

Protein Crisps

-

Melt-Away Puffs

-

Toddler Snacks

-

Direct Expanded Snacks

-

Fiber Twigs

-

-

Flaking

-

Drying & Toasting

-

Coating

-

Multi-Component Blending

-

Continuous Granola Production

- Molded Chocolate Bars / Layered Bars

- Paste Transfer

- Heating

- Pumping

- Mixing

- Blending

- Tempering

- Cooking

- Depositing

- Sheeting

- Cooling

- Forming

- Frosting/Glaze

- Mixing

- Heating

- Liquification

- Cooling

- Whipping

- Filling

Certifications & Food Safety

We are committed to fostering a robust and proactive food safety culture. This commitment drives regulatory compliance, certification excellence, and ongoing improvement. Our Food Safety & Quality Team ensures the highest food safety and quality standards are met, and plays an integral role in the end-to-end product development process.

Certifications and Claims We Support

Social & Environmental

Of equal importance is our commitment to the highest standards of social and environmental performance. We are focused on employee health and safety, employee relations and diversity, equity and inclusion. We are committed to lessening our impact on the environment by partnering with customers on sustainability initiatives. And we are dedicated to increasing employee engagement and value across all our locations.

Research & Development

Our Product Development team brings passion and decades of culinary, food science and operational experience to the table. Whether creating new flavors, optimizing ingredient costs, or developing unique new formulations, our product development team generates ideas that are rooted in consumer insights, on brand, differentiated from the competitive set, and feasible to manufacture. From ideation through full scale production, we collaborate with you every step of the way and strive to make the impossible possible.

- Ideation

- New Product Development

- Sensory Evaluation

- Shelf-Life Evaluation

- Pilot Line Trials

- Plant Trials & Testing

- Specification Development

- Regulatory Compliance

- Commercialization

- Product Optimization

- Project Management

- Troubleshooting

Engineering

As an integral business partner, Roskam Engineering has the process, mechanical, and electrical engineering expertise in-house to quickly provide project feasibilities, capital assessments and estimates. We collaborate closely with our customers to design and implement solutions that enable growth and flexibility while optimizing operational performance.

- Feasibility Studies

- Capital Assessments

- Line Designs

- Line Modifications

- Plant Trials

- Commercialization

- Packaging Development

- Specification Development

- Cost Savings Initiatives

- Capital Project Management & Execution

- Troubleshooting

Packaging

Our Engineering team provides technical leadership through all phases of packaging development including material selection, packaging design, testing, optimization, and implementation. We are well versed in a multitude of primary and secondary packaging structures to fit your brand and channel-specific requirements.

Primary Packaging

- Vertical Bags (pillow, gusseted)

- Horizontal Bags (stand-up resealable pouch)

- Flow and Shrink Wrap

- Single-Serve Cups

- Dual-Compartment Cups

- Single & Multi-Serve Trays

Secondary & Tertiary Packaging

- Cartons

- Bag in Box

- Multi-Component Kits

- Automated, Semi-Automated, and Manual Case Packing

- Tray and Bundle Wrap

- Promotional Displays

- Bulk Bags, Totes, Supersacks

Supply Chain

We offer an end-to-end view of your supply chain and logistics needs. With full EDI capabilities and integrated technologies, we act as an extension of your team from ingredient sourcing to final product delivery. Our reliability of supply is yet another way we build trust with our customers.

- Material Sourcing

- Demand Planning

- Supply Planning

- Capacity Planning

- Scheduling

- Allergen controlled warehousing

- Multi-temp storage and distribution

- Logistics